what tools do you need to mount pc under desk

Tools

There is much more to tools for electronics than just screwdrivers and

pliers. While most of the mutual tools can exist found at a local hardware or

abode comeback store, many are unique to the electronics

industry. These specialized tools accept evolved over many years, in some

cases starting out every bit modified versions of mutual hardware shop types,

and in other cases designed from the kickoff to fulfill a specific need.

For the most part, yous shouldn't need to spend a lot of money on odd-ball

tools if you stick to the common hardware described in not available

and avert things like surface-mounted components with ultra-fine pitch leads.

If you need to use an integrated circuit (IC) with something like 144 leads with hair-width spaces betwixt the leads, and then you should probably consider paying someone to mountain information technology for you using screened solder paste and a reflow soldering system. For but a single project, it might non be worth the expense of acquiring a decent demote microscope and a fancy surface-mountain soldering station and and so learning to apply it.

Learn faster. Dig deeper. Run into farther.

This affiliate is a survey of some of the common tools you should consider

owning for working with modern electronics. It is not intended to be a

definitive or comprehensive guide. There are paw tools, ability tools, and

bench-mounted tools for tightening, cutting, drilling, and trimming. Other

tools are used for soldering, inspecting, and finishing. I would propose

obtaining a selection of catalogs from companies such every bit Digikey and Mouser

and perusing the tool sections. If you take a good electronics supply

outlet nearby, it might be useful to browse its display racks to get an

thought of what's available and examine the tools in person.

Warning

Some of the tools described in this chapter tin severely hurt you if used

incorrectly or carelessly. E'er article of clothing safety glasses when working with power

tools, and always read and follow the manufacturer's safe precautions

provided with the tool.

Screwdrivers

For every screw type there is a screwdriver. For virtually tasks, a bones selection

of screwdrivers, such every bit the ones shown in Effigy 1-ane, is all y'all'll need.

Nonetheless, if you plan on disassembling consumer electronics or a toy, and then

you might likewise need some rather odd screwdriver types. A set of miniature

and specialty screwdrivers, such as the one shown in Figure ane-2, is essential for these types of situations.

You tin can find sets like this on eBay. Merely bear in listen that these imported tools are generally not made from the highest-quality metal (that'due south why they are so inexpensive), and they can be easily ruined if used incorrectly.

Combination driver sets are bachelor that employ a common handle and a selection

of driver $.25. Figure one-three shows a set up with slotted, Phillips, hex, Y,

and other styles.

Tip

Although cheap combination sets might seem like the respond to

all your commuter needs, you should bear in mind that you go what y'all pay for.

The tool bits in these sets aren't e'er fabricated from the all-time metal and tend

to be brittle. The handles tin can as well become loose or fifty-fifty break if stressed likewise

much. That being said, sometimes the only place to find that oddball driver

you lot really need is in 1 of these imported combination kits.

Pliers

The pliers available from a hardware shop or other locations are

acceptable for many tasks, but they are not e'er ideal for working

with electronics. Figure 1-four shows a selection of typical tools

yous might observe at an auto parts or dwelling improvement store.

The big jaws of the common pliers are good for gripping stubborn bolts

or property a stiff leap while maneuvering it into position. But those

aforementioned big jaws cannot really bargain with things like resistor leads. For

that type of task, y'all need a different tool.

Specialty pliers are bachelor with narrow tips, and fifty-fifty with a 90-degree

bend. Needle-olfactory organ pliers, shown in Figure 1-5, are a common

tool in whatever electronics toolbox. Just, as with whatever tool, they are intended

for a specific set of applications, which are discussed in not available.

So-called lineman's pliers are a familiar tool for anyone who deals with

household or industrial electric wiring. They were originally developed

for employ by electrical linemen, hence the proper name. These tools are rugged and

versatile and can be used to curve large-gauge wire, cutting screws and small

bolts, and pull cable through narrow channels or conduit, and some types have

cut-outs to crimp lug-type connectors. They are sometimes used to hammer a

screw or concrete anchor into a starting position, earning them the

nickname of electrician'due south hammer. Effigy 1-six

shows a typical example. You can find them at hardware and abode improvement

stores, online suppliers, and virtually electrical supply outlets.

Wire Cutters

As with pliers, the typical wire cutters from the hardware store are

suitable for cutting wires for home wiring and automotive work, but they

are non designed for electronics. Specialty cutters are available with

blades designed to cutting affluent against a surface to trim component leads

on a printed circuit board (PCB) as close as possible, and some types accept built-in retainers to

preclude cut leads and wires from flying off. Figure i-7

shows the so-chosen flush cutter type, which is almost commonly

used in electronics.

The diagonal cutters shown in

Figure 1-viii, along with a pair of cease cutters (also known

as nippers), are mutual types of wire-cut tools. Equally mentioned earlier, these are not designed specifically

for electronics piece of work, but they can, and should, be used for tasks

that are also enervating for the flush cutters.

Diagonal cutters come up in a range of sizes, from pocket-size ones similar the tool

shown in Figure 1-8 to big cutting tools used past

electricians and in industry. The end cutters are useful for nipping

off wires close to a surface and can be used to (carefully!) remove

small brads or finishing nails, provided that you are careful non to

use excessive strength and put a notch in the blades.

There is i important matter to proceed in mind when you are using wire cutters

intended for electronics work: do not cut difficult items that can create a

nick or notch in the blades. In other words, utilize a pair of lineman'south

pliers or heavy cutters for things like clothes hanger wire or spring

steel, diagonal cutters for large-gauge insulated wire, and flush

cutters for the leads of components and thin wire simply. In one case your

flush cutters have been nicked, that portion of the blade is useless

(except perhaps for stripping small-guess wires, merely at that place are ameliorate

tools for that).

Wire Strippers

Trying to strip the insulation from wire using something like a pair of

affluent or diagonal cutters is risky, at best. Unless you are very, very

good, at that place is a distinct possibility that the wire volition be nicked, and

when that happens, the nicked spot tin can cause the wire to break. Some types of pliers include built-in wire strippers, but they don't always

piece of work that well, and they are fixed for one size of wire. A better pick

is a tool made specifically to strip wires, similar the one shown in

Figure 1-9.

You can conform the wire strippers shown in Figure 1-ix using the fix

screw seen on the lower handle. If set correctly, they will do a good job of

removing most types of insulation without damaging the underlying wire. Manual

wire strippers similar these can be adjusted to whatever wire size from 10 down to

24 AWG (American wire gauge), but they can be difficult to employ on larger wire gauges.

At that place are, of course, fancier wire strippers bachelor, such as the automatic

strippers shown in Figure 1-ten.

Automatic wire strippers cut and remove upwards to 1 inch of insulation in i step,

repeatedly removing the same amount of insulation each fourth dimension. The tool

shown in Figure 1-10 handles viii- to 22-approximate wire, and a replacement

blade fix is available for 16- to 26-guess wire.

Equally yous might expect, there are likewise electrical versions of automatic wire

strippers. These are expensive heavy-duty tools intended for production line

work, and they aren't something usually found in a typical modest shop.

There is also a style of tool that incorporates lug crimper, machine-screw

cutter, wire cutter, and wire stripper capabilities into the same tool. These

are common in hardware stores, but I don't recommend them as wire strippers.

When this type of tool is used to strip wire, information technology has a tendency to pull on the

insulation rather than cutting it cleanly, and sometimes the tool just doesn't have

the right stripper pigsty for the wire. With the two types of stripping tools

shown here, y'all can either set the tool for exactly the correct size or you can

rely on the blade set and grabber jaws to do a clean job without requiring

you to wrestle with the wire.

Crimping Tools

If you are working with connectors that utilize crimped terminals, then

a crimping tool is essential. There really is no other manner to brand a good

connection with these types of connectors. Rectangular connectors that utilize

insertable socket terminals are readily available, and they come up in a diversity

of styles and sizes. Crimping tools range from simple things that wait

like pliers to aerospace-form ratcheted devices with interchangeable

crimping parts, called dies, for different contact sizes. Effigy i-eleven

shows a relatively inexpensive tool for working with crimp contacts like

those used in rectangular connectors. The tools range in price from around $30

to well over $500.

Do not try to use a crimping tool from an motorcar supply or hardware store

for miniature electronic connectors. It won't work. Those tools, like

the one shown in Figure i-12, are made to be used with connectors

such as the spade lugs and butt splices institute in automotive wiring,

and for those types of applications they are fine. They simply won't piece of work

with the extremely small concluding parts used in miniature connectors.

Note that the crimping tool in Figure 1-12 has other things going on

besides the crimping points. A tool like this can cut and strip wires,

as well as trim machine screws. Information technology can come in handy in an electronics

store on occasion, but it might not run across a lot of heavy use.

Note

Try to utilize the correct tool made for specific contacts or terminals. Y'all

may end up with a collection of crimp tools (that's typical), merely when

you need a tool, only the right tool will do the job correctly.

Lastly, if you plan to piece of work with things similar the "F" connectors used with

cable Television set wiring or make your own Ethernet cables, and so you'll demand crimp

tools for those applications. You tin find tools for video and telephone

connectors at a well-stocked home comeback store, and there are multiple

sources of RJ45 Ethernet-cable-making kits available online.

Socket and Hex Drivers

You tin can find a basic socket prepare at whatsoever auto parts, hardware, or abode

improvement store. These sets typically have socket sizes ranging from 1/4 inch

to three/4 inch, with some going smaller and some larger. Information technology depends

on how much yous are willing to spend. Sockets come in metric sizes as

well. Figure ane-thirteen shows a typical kit in a plastic carrying case.

But, similar many other mutual tools, these sets are non intended for the

electronics industry. Rather, they are designed for automotive and other

heavy-duty applications. Still, it is a good idea to have a decent

socket set around.

Socket drivers made specifically for electronics piece of work usually don't come

with the ratchet. Rather, the kit is a set of tools that plug into a common

handle, or each tool has an integrated handle, like the set shown in

Figure one-14.

Also notation that the combination tool kit shown in Figure 1-3 comes

with seven metric sockets, and however other kits are available with long (i.east.,

deep) sockets that can fit over a protruding spiral or bolt shaft.

For hex-socket-caput screws and bolts, y'all need a hex wrench or hex central,

also called an Allen wrench. These come in

both ANSI/ASME (i.e, English language) and a typical small set in a holder is shown in Figure i-xv.

These hex wrenches have brawl-type ends, and thus are sometimes referred to

equally ball drivers. This is a handy characteristic that allows the wrench to use

torque to a fastener without having to be directly aligned with the

axis of the bolt or spiral. As y'all can too see, this detail set up already

has some milage on information technology, but that'south all right. Tools don't have to be pretty to

work well.

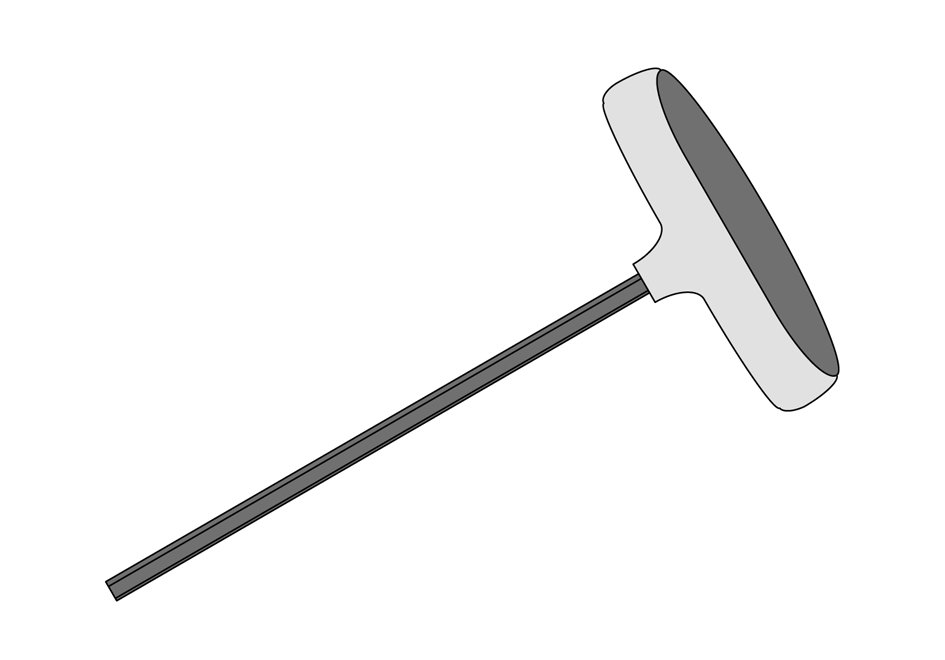

I would non recommend the so-called T-handle tools,

such as the case shown in Figure ane-sixteen, for electronics work, mainly due to the expense,

only that'south largely a personal choice. This type of tool is pop in the

optical sciences, where information technology is used to make fine adjustments to lens

mounts and mirrors, and information technology is sometimes found in aerospace fabrication

environments. These tools are less frequently seen in electronics labs or shops,

nonetheless.

I would recommend getting sockets and hex wrenches in both ANSI/ASME and

metric sizes, especially if you plan to hack an existing consumer or industrial

device of some type. Most consumer electronics these days are assembled using

metric fasteners, simply a lot of industrial equipment made in the US is still

ANSI/ASME.

Clamps

Clamps are designed to exert pressure to hold something, whether that is a single

piece of wire, an electronic component, or two pieces of metallic. Clamps may be locked or screwed into position, and they retain the pressure on

whatever they're gripping until released. Technically, even a mutual

alligator clip is a type of clench, and information technology tin exist found in that role equally function

of and so-chosen "third-manus" gadgets like the ane shown in Figure 1-17.

Some types of clamps look like thin jaws with scissor-like

handles. Likewise known every bit hemostats, these are just repurposed medical tools.

Figure 1-18 shows some of the various types that are available for purchase

from multiple sources. In the past, tools like this were used

as heatsinks for soldering things similar transistors into a indicate-to-point

excursion. With the widespread adoption of printed excursion boards and

temperature-controlled soldering irons, it became possible to solder parts

onto the PCB without worrying too much about thermal damage (assuming, of

class, that the person wielding the soldering iron has a good technique

and doesn't loiter besides long on the connectedness).

A hemostat is useful when yous demand to concur some parts in identify for soldering,

such equally 2 pieces of wire or component leads. They are likewise useful for property

things while an adhesive sets or for simply keeping something out of the mode.

For larger jobs, in that location are various types of clamps available, from miniature

C-clamps to plastic spring-loaded devices that await like clothes pins on

steroids. Many of the clamps employed for woodworking tin can also exist used for

electronics work, so long equally you continue in listen that things can go hot, and

plastic clamps intended for wood might not fare well if the work pieces they

are holding get too warm.

For dealing with metal, the ever-popular C-clench is ofttimes a good first

pick. Figure 1-19 shows some of the types available. I recommend

keeping several of the smaller ones in your toolbox. You may or may not

ever need the larger sizes, but having a couple effectually is not a bad thought.

Vises

A small vise is an essential tool in any shop. Figure ane-20 shows one blazon

of demote vise commonly used in electronics work. Unlike its larger cast and

forged cousins, this vise is lightweight, the caput can rotate and swivel into

various positions, and the jaws are padded with plastic strips to prevent

harm to delicate items. This one happens to be made by PanaVise, and it

consists of a model 300 base of operations and a model 301 vise head.

The small-scale vise shown in Figure i-xx can also exist incorporated into a compact

workstation, equally shown in Figure 1-21. In addition to the vise itself,

it includes a soldering iron holder, circuit board holder, and a heavy base.

This is a PanaVise model 315 circuit board holder with a model 300 base, all

of which is attached to a larger base that has holders for a soldering iron

and a spool of solder. It too also recessed tray spaces in the base to hold

soldering-iron-tip cleaning sponges.

The vise shown in Figure 1-20 isn't suitable for bending metal or hammering

out a stuck steel alignment pivot. For that yous demand something like the one

shown in Figure 1-22. A big downside to a tool like this is that it actually

needs to take a permanent location—a very solid permanent location. So unless

y'all recollect you might need to exercise some light metalwork, you can probably forgo the

heavy-duty vise.

A somewhat smaller version of Figure 1-22 is shown in Figure one-23. This model is

designed to clamp to the edge of a table or workbench, and it'due south suitable for many

lightweight tasks.

Rotary Tools

A good rotary tool is one of the nearly versatile tools yous can own. At that place are

many types available, ranging from the very cheap and somewhat flimsy to

substantial tools suitable for production-line use. Some models come up with

a selection of speeds, and some have continuously variable speed control.

A rotary tool is extremely useful for cutting small square holes in a plastic

box, trimming a slightly oversized printed circuit board to fit into an enclosure,

drilling holes in a PCB, and performing other tasks that require a small-scale tool with a lot

of attachment options. Figure 1-24 shows a typical unit with variable speed.

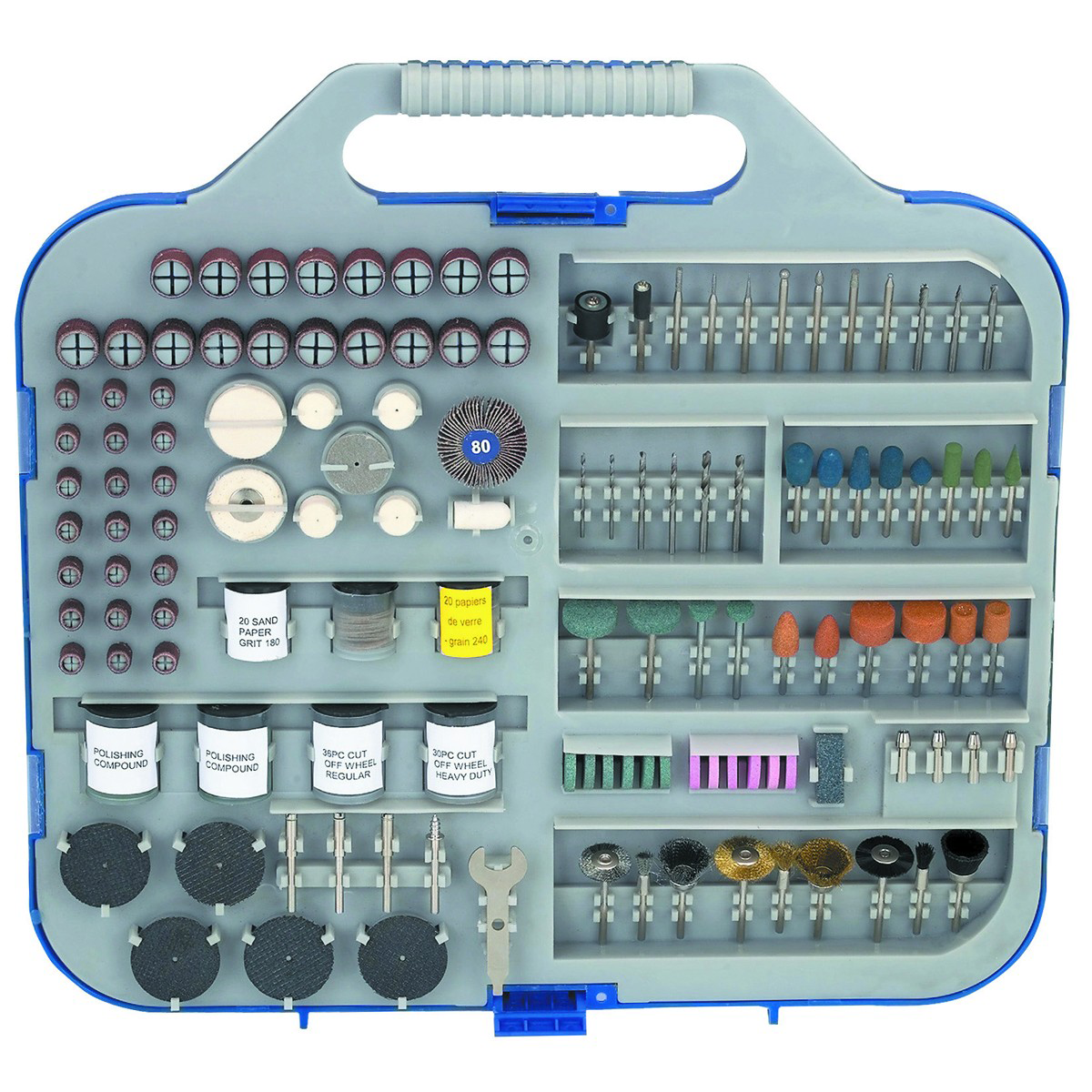

You can also purchase a choice of diverse attachments for

rotary tools in the form of kits from most hardware stores and home

comeback centers, as shown in Figure one-25. Of all of these,

the virtually useful attachments are probably the miniature cut-off disks,

sanding drums, and cutting tips. I purchase the cut-off disks in bulk packs,

as I tend to get through them rather chop-chop. If y'all are building highly detailed model

ships or custom jewelry, the other attachments might likewise be useful, but they aren't really essential for

electronics work.

Ane thing to keep in mind when considering a rotary tool is that the

various attachments all apply the aforementioned shaft size, typically 1/8 inch, and

the chuck (the part that grips the shaft) is designed for only that size.

In other words, you can't grab a 9/64 drill bit and look it to work. It

won't, not without an adapter or a different chuck. While a drill comes with a

chuck that can be adjusted to accommodate $.25 of different diameters, a

rotary tool usually doesn't.

Tip

A rotary tool is not really a drill. With the correct bit, it tin can be used as a drill

for soft materials and printed circuit boards, but it does not have the torque of

a real drill. It is easy to fire out a rotary tool by using it for something information technology

wasn't intended for, so if you need to drill holes, you really should

attain for a drill.

Grinders

A small bench grinder is a handy thing to take. Grinders in general are useful

tools to have, and they tin can save you a lot of time when yous need to shape the tip of a screwdriver, take the

corner off a bracket so it will fit, or clean upwards the edge of a piece of aluminum

or clear acrylic. You tin pick up one like the unit

shown in Figure 1-26 from Harbor Freight for around $forty, and some models come

with a detachable flex-cable rotary tool, like the one shown.

Unless y'all plan to sharpen lawnmower blades or undertake another heavy-duty

action, you probably don't need a heavy-duty grinder. These devices have

high-power motors, oftentimes come up with built-in piece of work lamps, and are available in

both bench and flooring-mount versions.

A tool that I've constitute to exist extremely useful is a correct-bending grinder, similar

the one shown in Figure 1-27. You might non always need it, merely when the

demand does arise, there is really cypher else that can do the job as quickly and

efficiently as this tool. You can use it to cut small-diameter metal extrusions

and tubing. Y'all tin can also use it to remove the cease of a machine screw or bolt that is

protruding also far by a nut, or to remove the caput of a bullheaded rivet or

ruined screw without resorting to drilling. Information technology can also be used to slice upward an

aluminum chassis if you want to utilise part of it for something else, and, if you use it

carefully, you can even cut square or rectangular access panels in a metal box.

The downside to the right-angle grinder is that it is a loud—very loud—and powerful tool.

It is also rather unsafe, and it can inflict serious injuries very

apace if you let it get away from yous. Always employ the side grip handle, vesture heavy

gloves, use middle protection, and never try to operate the tool unmarried-handed. These

tools aren't well suited to doing fine, detailed work (use a rotary tool for that),

but they tin can piece through metal tubes, pipes, or extrusions with ease.

Drills

Electric hand drills are useful for a lot of things, but drilling a precise

pigsty typically isn't one of those things. A pocket-size drill press is essential for

drilling holes for screws, switches, LED indicators, or connectors. While you

might be able to do a passable chore with a common electric hand drill, the

chances of slipping, creating an off-axis pigsty, or accidentally making the

pigsty also big because of tool vibrations are swell. If y'all want a

clean, precise hole, use a drill printing.

That existence said, a mitt-held electrical drill is an essential tool for the shop.

When you just need to brand a quick pigsty, drill out a rivet, or apply it with a

driver bit to drive in a screw, an electric manus-drill is handy to have effectually.

I recommend a bombardment-powered type like the one shown in Effigy 1-28.

For doing precision drilling, a drill press is essential. You can get a decent bench-peak

drill printing like the ane shown in Effigy 1-29 for around

$70 (this 1 came from Harbor Freight), and in that location are besides rigs that allow a

standard manus-held electrical drill to be clamped into a drill-press-type fixture.

These are all right for light jobs, but they practise require care when you lot're mounting the

drill. If you need to remove and supersede the drill oftentimes to handle dissimilar

tasks, and so a dedicated drill printing would probably be a better alternative;

information technology's less tedious to deal with and it saves wear and tear on the paw-held drill.

Drill Bits

The drill, be it manus-held or some type of drill press, is but a

mechanism for spinning a tool. The working tool in a drill is the drill

chip. Sets of drill bits in various sizes are widely bachelor,

in a multifariousness of cases and holders. These range from small kits, like the

one shown in Figure 1-thirty, to large sets institute in car

shops and industrial settings.

Not all drills are created equal, and near of the depression-price drill bit

sets contain $.25 that will not stand up to extended or heavy utilize. The

metal used to brand the drills simply isn't that corking, and a couple of

attempts to make a hole in something like steel will chop-chop dull

the tip. There are means to drill a pigsty with lubricants that tin can aid

to reduce the wear and tear, but they won't stop it. not bachelor discusses recommended ways to

apply drills.

Some drill $.25 are intended for special-purpose applications, such as

drilling the holes in a printed excursion board. Effigy 1-31

shows a choice of these types of drill bits. Notice the colour-coded

plastic collars on the bit shanks. In that location are standard twist drill bits

bachelor with one/8-inch shanks that can exist used with a rotary tool, and yous can

typically find them wherever rotary tools are sold.

You can likewise detect PCB drill bits listed as surplus items, mainly considering

the materials used to make PCBs tend to be hard on drill bits and they quickly become

too dull to meet manufacturing standards. But, equally always,

caveat emptor. You may end up with a collection of deadening or broken drills

that are substantially useless. Meliorate to spend a bit more and get one of

the imported sets of new bits. They might not be top quality, but with

conscientious use, they will practise the job.

Annotation that small drills bits like those shown in Figure one-31 are

useful for soft materials like plastic or wood, and of course they will

brand a pigsty in a PCB if they are sharp. In general, these types of drill

bits will not work well with difficult metals, but they tin be used with soft

metals like atomic number 82, silver, and gilt.

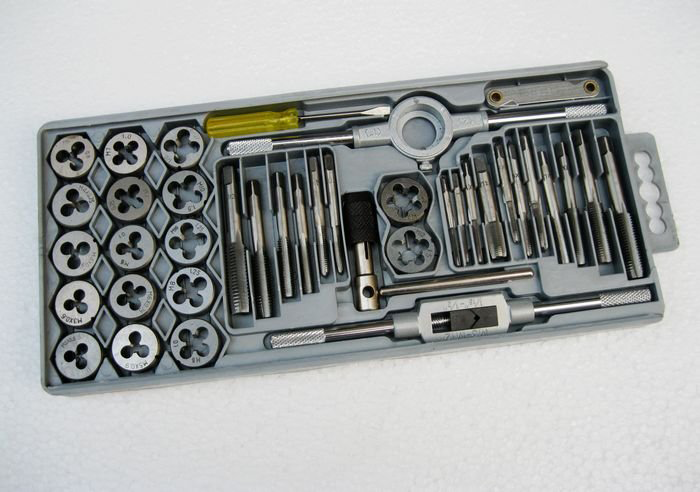

Taps and Dies

Sometimes you lot really need a threaded hole, or peradventure you want to make a

special-purpose threaded shaft. Tapping is the process of cutting

threads into an appropriately sized hole with a tool chosen a tap. A

die is a tool for cutting threads into a blank rod to create a threaded

shaft, and it is also sometimes used to repair damaged screw or bolt

threads. Figure 1-32 shows an cheap tap and die kit.

A tap and die kit is handy to have effectually, merely it must be used with care to

avoid damage to the tools. It'south like shooting fish in a barrel to break off a small tap in a hole

that was drilled to the wrong size. not available discusses some ways to employ

both taps and dies to get successful results.

Small Hand Saws

A pocket-size saw is useful for cutting things like tubing and sections of sheet

materials. Specialty saws, such every bit a jeweler's saw, are extremely useful for

creating odd-shaped holes in things.

Figure 1-33 shows a type of miniature hacksaw that is readily available

at hardware and home improvement stores.

These tools will take a standard hacksaw blade, and they are useful for

getting into tight places. They do not have the same caste of stability that

you will get with a regular hacksaw, still, because the blade isn't tensioned

at both ends.

For doing particular work or creating minor holes with odd shapes, something similar

the jeweler's saw shown in Figure 1-34 is the way to go.

A jeweler'southward saw uses a very narrow blade. This allows information technology to brand sharp turns

without binding, only information technology as well means that it easy to snap the blade if you apply too much

force while cutting. Figure 1-35 shows a pack of blades for a jeweler's saw.

Miniature Power Saws

Since electronics often involves working with things that are minor,

there normally isn't a need for something like a full-up table saw or

cutting-off saw. Still, you will find that there is frequently a demand to cutting plastic or metal

tubing, aluminum extrusions, or pocket-size plastic or soft aluminum panels.

For jobs like these, miniature tools are available, like the little

table saw shown in Effigy 1-36.

This handy device uses a standard four-inch blade, and although it's somewhat

clumsy to adjust, it does have a height aligning. The blade is fixed in

the vertical position, so it won't do angle cuts. You can find it for about

$40 or so at places like Harbor Freight. Note that the table expanse is

small, so information technology isn't suitable for anything larger than about 12 inches in size.

You could, with a petty endeavour, build tabular array extensions for it to handle

larger items, but then you would exist treading into the territory of

full-size table saws.

For cut tubing, extrusions, rods, or other long, thin items, a cut-off

saw with a grinder blade is a handy tool. Besides known as a chop saw, a

cutting-off saw will produce a nice, clean cut, without the roughness and

jagged edges that can result when a hacksaw is used. It'due south a lot quicker,

as well. Figure 1-37 shows ane of the diverse types of miniature cutting-off saws that are available. They range in cost from around $forty

to over $300, depending on the brand, quality, blade size, and number

of boosted features. Annotation that some of these types of tools will

work merely with a grinder bike, not an actual saw blade.

The chief advantage of modest saws like these is their convenience and

ability to deal with minor work pieces. Just proceed in mind that, similar any

powered tool, these are not toys. Although they are miniature versions of

the total-size tools found in metal and woodworking shops, they can still

cut you badly. Losing a finger with careless use is a distinct

possibility, only as with their larger cousins.

Specialty Metalworking Tools

If you will exist working with metal, there are some tools that you

actually should consider having in your toolbox. Metal tin can be a frustrating

material to deal with, and having the right tool for the job tin make

the difference betwixt badgerer and satisfaction.

When y'all are drilling or cutting a pigsty in sheet metal, the effect ofttimes has

sharp edges or fiddling bits of leftover cloth called burrs. This is

particularly truthful when you lot're working with the soft, untempered aluminum used

for sheet-metal chassis parts. Steel pieces don't endure quite every bit much from

this, simply drilling a 1/2-inch hole in a piece of 18-judge steel tin can sometimes

outcome in a somewhat ragged hole. This most often happens when y'all effort

to make a hole without going through a series of pace-upward holes outset

(encounter not available for drilling techniques), which is a common mistake of

the impatient.

A deburring tool, as shown in Effigy ane-38, is essentially a swivel

blade set in a handle. It is used in a circular motion to trim the inside

of a pigsty or cut-out, removing burrs and helping to polish out the cut.

These tools are inexpensive and readily bachelor from a variety of sources.

Creating a starting point is a good idea when working with metal. Even

when you're using a drill press, a location betoken can help get the drill started to

make a clean pigsty. The automatic punch, shown in Figure i-39, is

designed to accept the place of a hand-held punch and ball-peen hammer. To use

it, yous simply push downwards until the internal spring-loaded mechanism releases,

which causes the tip to create a minor indentation in the material.

The concept of step-up drilling was mentioned earlier and is discussed

in non available, only there is a tool that makes the process easier (which

should not exist surprising, since there seems to exist a tool for every

conceivable use). This is called a footstep drill, and a typical pace drill

prepare is shown in Figure i-twoscore.

A pace drill is best suited for soft materials, such as plastic, soft

aluminum, or mild steel every bit found in electric boxes. Stride drills are

often used by electricians to make conduit holes in electric enclosures.

They can be used with hard materials if the tool is suitably hardened and

rated for that kind of application, but many of the low-cost pace $.25

won't accept much abuse like that before they become useless.

Brave and assuming electricians all the same, I would suggest that a footstep

drill be used with a drill printing if possible, since it can potentially

demark in the hole and twist the drill out of your easily. An electric drill

can spin effectually and hit your hand earlier y'all can motion it out of the way,

and you could end up with a broken os or ii. At the very least, yous

can get a prissy bruise if a drill gets away from you.

A good set of step drills tends to be rather pricey, running up of effectually

$100 for a set of iii, but single drills tin can exist had for a low as $10 each.

When buying a step drill, get the best one you tin can afford.

Tweezers

A good pair of tweezers is invaluable for working with small-scale parts that

needle-nose pliers won't hold safely or reliably. Tweezers for electronics

work come in a range of styles, every bit shown in Effigy i-41.

In addition to tweezers that operate similar the ones found in a home

medicine chiffonier, there are besides self-closing types, where y'all take

to strength the tips apart rather than forcefulness them together. It's not a bad

idea to accept at least i of both types in your tool kit.

Soldering Tools

A decent soldering iron or a soldering station is absolutely essential for

working with electronics. Avoid the cheap soldering irons, as they won't

hold upwardly to heavy use and they don't concord their tip temperature reliably.

Please don't fifty-fifty consider a soldering gun for electronics work (fifty-fifty

though old Heathkit manuals testify them existence used to assemble vacuum tube

equipment). A soldering gun is typically used for connecting heavy gauge

wires and copper tubing, not for working with components on a PCB. In fact,

if you happen to own a soldering gun, I would suggest hiding it so you won't

ever be tempted to take hold of information technology in a bustle. Meliorate yet, throw information technology away, donate it,

or convert it into a low-cost spot welder. Figure one-42 shows a low-toll temperature-controlled

soldering fe.

Companies such as Weller make fantabulous industrial-course soldering stations

with continuous temperature control and grounded tips to reduce possible

damage from static discharge. A multifariousness of tip sizes and styles is bachelor,

ranging from something like a slot screwdriver to very fine points for surface-mount technology (SMT) piece of work. Figure one-43 shows a low-cost soldering

station sold by Velleman, which includes the tool holder and a control unit of measurement to

regulate the tip temperature.

Working with surface-mount parts requires soldering tools that are capable of working

with pocket-sized parts and closely spaced leads. Soldering stations for surface-mountain

piece of work can exist rather pricey, particularly for the stations that besides include a

hot-air attachment. The good news is that a soldering station like the i shown

in Figure 1-43 will handle a lot of SMT tasks if used with a fine tip

and the advisable temperature. not available discusses soldering temperature in more detail.

Effigy 1-44 shows a soldering station specifically designed for working with surface-mount

parts (this 1 is X-TRONIC model number

XTR-4040-XTS and is available through Amazon.com). In add-on to the soldering

iron with a fine-point tip, it also has a hot-air blower with a selection of

nozzles. The hot air is used to desolder or rework a surface-mount function. The kit

comes with the magnifying light shown. In not available, we'll look at how to work

with surface-mount parts in more detail.

Magnifiers and Microscopes

If you programme on working with surface-mounted components, and you lot value

your eyesight, you should consider purchasing some type of magnifier

or low-power microscope. A truthful stereo microscope is all-time, simply of course

information technology is also more than expensive than a simple single-objective blazon. Figure 1-45 shows a low-price

stereo microscope.

The types of cheap microscopes sold as toys for children are useless for electronics

work, as are more than high-end laboratory microscopes used in medical and biological science piece of work.

The image quality of toy microscopes is usually rather bad, and both types typically

accept also high a level of magnification to be usable. An industrial microscope for electronics piece of work is designed to provide a decent level of magnification (betwixt 5X and 10X is typical, and some are adjustable) while still maintaining a relatively wide field of view. You won't be able to wait at microbes in pond water with i of

these, but y'all volition be able to clearly see the leads on a TQFP144 surface-mount IC

package.

The stereo microscope in Figure ane-45 was acquired for nearly $100 as a

surplus (new overstock) item. Yous can find similar bargains on eBay or by checking

out some of the optical surplus companies found online.

Another culling—a handy item mentioned in Clamps—combines a

magnifying drinking glass with a pair of clips, as shown in Figure 1-46. It doesn't

provide the same level of magnification as a microscope, but for many applications

it's merely fine.

Lastly, there are bench lamps with built-in magnifying lenses, like the

ane shown in Figure 1-47. Some are big plenty to allow you lot to

look through the lens with both eyes at once, so you tin get a sense of

depth.

As a last resort, there are the jeweler's loupe and pocket magnifiers, like

the one shown in Figure ane-48. The pocket magnifier, with its

multiple lenses, is popular with geologists and rock hounds. It's also

useful for electronics work, but it does require a mitt to concur information technology and

it needs to exist adequately close to whatsoever y'all want to await at.

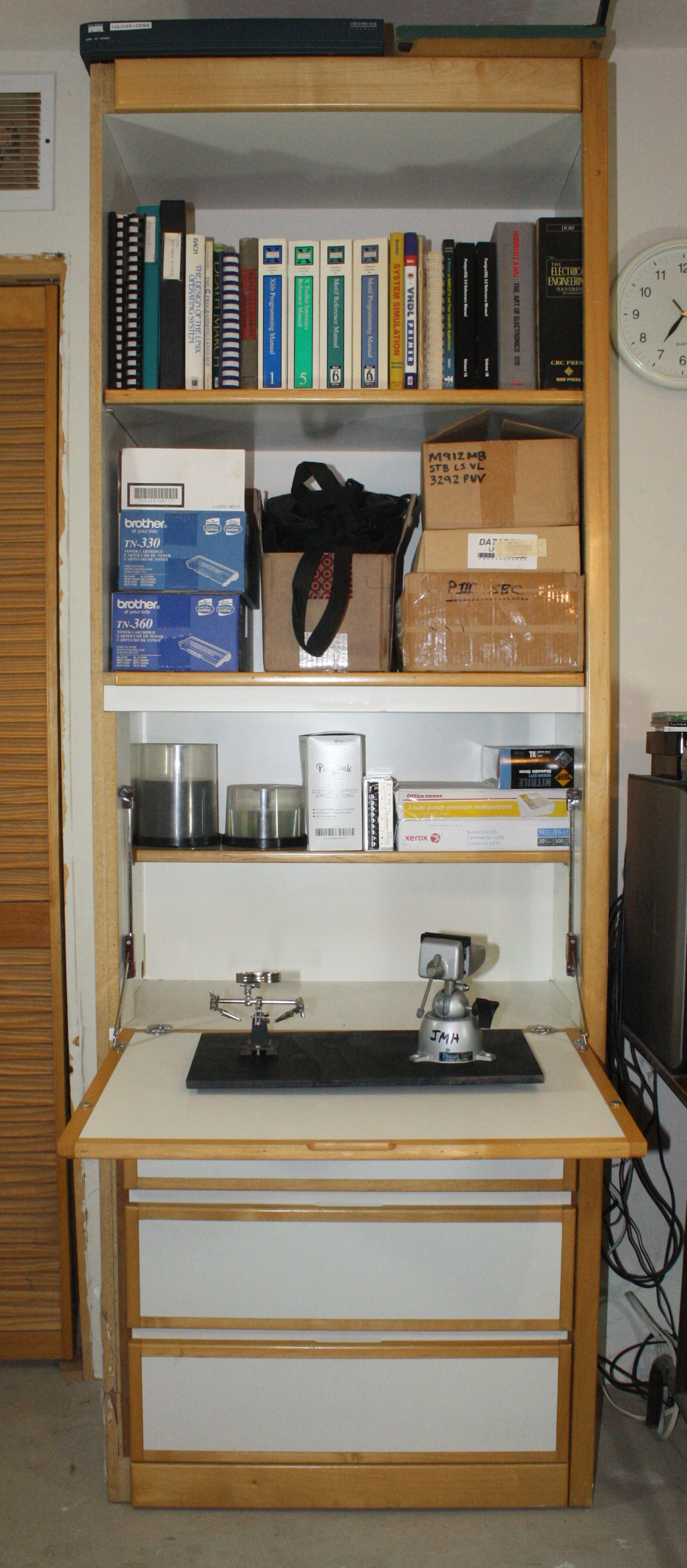

Workspaces

Having a lot of tools on mitt is smashing, but only if you as well have a place

to shop them and use them. If you have tight quarters, a surplus

combination cabinet and shelf unit of measurement like the i shown in Figure one-49

might be just the thing. This item item looks like it came out of

a dormitory, or mayhap an efficiency apartment, and it was purchased for

almost $xl.

This setup has a lath with rubber feet under it property a

small vise and an articulated work holder (with magnifying drinking glass).

Above that is a shelf with various supplies, and the whole front

table folds up when it's not needed.

Things like the drill press, the miniature table saw, the cut-off saw,

and the soldering station really need to live on a workbench of some

sort. Y'all tin can buy relatively inexpensive workbenches from places

like Sears or Harbor Freight, or you could spend some serious coin and

get an industrial-grade, metal-frame workbench for several hundred dollars.

Another alternative is to repurpose sometime metal office and dormitory

piece of furniture. If y'all have a local college or university that holds periodic

auctions, information technology is possible to find some adept bargains. Some manufacturers

also concur auctions occasionally, and these are a good identify to pick up

used industrial-form fixtures (if you don't mind scuffs, dings, acid burns,

and other small-scale defects).

A adept toolbox is likewise essential. Effigy ane-50 shows a pocket-size, only overstuffed, toolbox.

Larger roll-around toolboxes, similar the ones

used past car mechanics, are prissy if yous take the space for them. A good

one that will concord up to years of use is not inexpensive, however. You tin get

a roll-effectually cheap, merely you'll more likely stop upward with just a inexpensive

gyre-around that won't last very long.

Lastly, yous can build overhead shelving for a table or desk for very

little money. If you apply standard shelf wood from a home comeback

store, all yous'll need to do is cutting the shelf planks to the correct

lengths and get together each shelf with some brackets, some screws, and a suitable

amount of wood glue, and yous'll have a handy identify to store books, parts,

and tools while leaving the table or desk surface open. Pigment is optional,

but information technology does look nicer.

Summary

From what has been covered hither, you lot should be able to gather up a minimum

set of tools for your projects. Every bit a suggested minimum, yous will demand

screwdrivers, pliers of various types, affluent and diagonal cutters, wire

strippers, lineman's pliers, hex wrenches, sockets, soldering tools, a

drill (and drill bits, of course), and a good gear up of files. A good pocket

pocketknife is also an incredibly handy affair to have.

In addition to checking electronics distributors, home improvement centers,

hardware stores, electronics suppliers, and online sources, you might

besides want to look around your surface area to meet if there are whatever surplus

or second-hand tool shops. You can find a broad variety of things at

low prices, although sometimes they practice need to be cleaned up or at least

readjusted before they are one time again usable. If, for instance, a shop

has a bench-top ring saw for $30 that really only needs to take the blade

guides adjusted, then that's something that might exist worth ownership. You lot

can also observe buckets full of used screwdrivers, pliers, and wrenches at

second-hand tool shops.

If you were to buy everything covered in this chapter, yous could

end up spending less than $1,000, depending on where you purchased it and

what level of quality you could tolerate. With some careful shopping,

you lot might fifty-fifty be able to get some of tools used and get the total down

to under $500.

A adept set of tools tin make all the deviation between success and failure,

but knowing how to use them and gaining experience is the other key ingredient.

In not available, nosotros will wait at some of the techniques used with various

tools.

hefleyandelibubled.blogspot.com

Source: https://www.oreilly.com/content/practical-electronics-tools/

0 Response to "what tools do you need to mount pc under desk"

Post a Comment